ZB 1250S-450

Characteristics

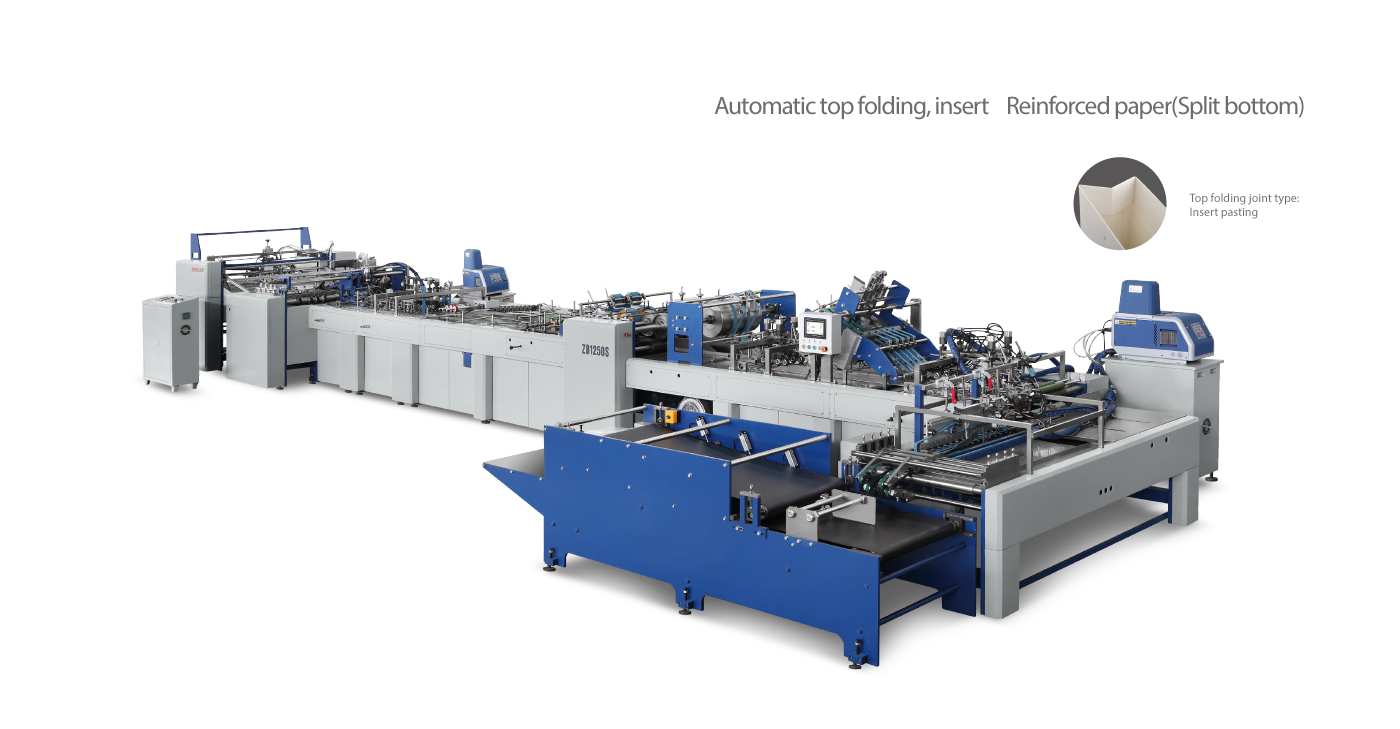

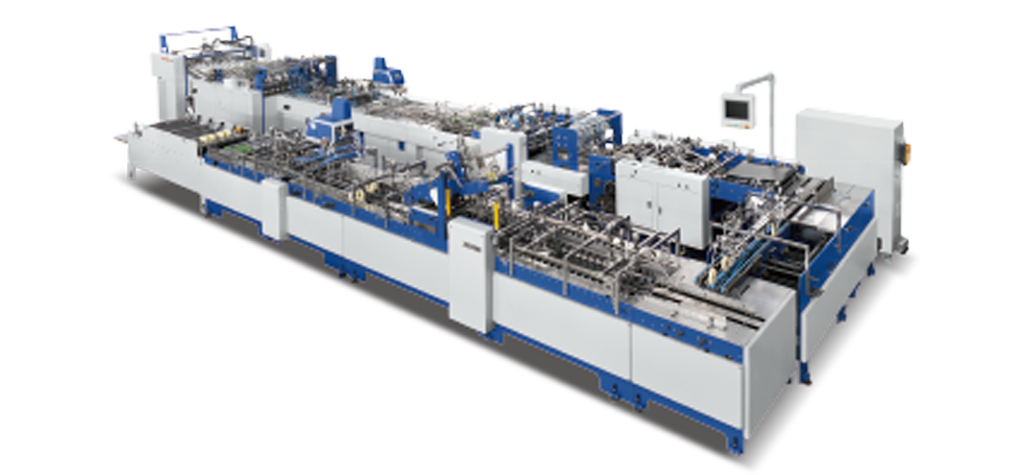

ZB1250S-450 Sheet feeding paper bag making machine (independent innovation), create the high-speed automatic paper bag production. This machine adopts with PLC and Servo control system, reserve of extensible intelligent port for future system upgrades and remote services.

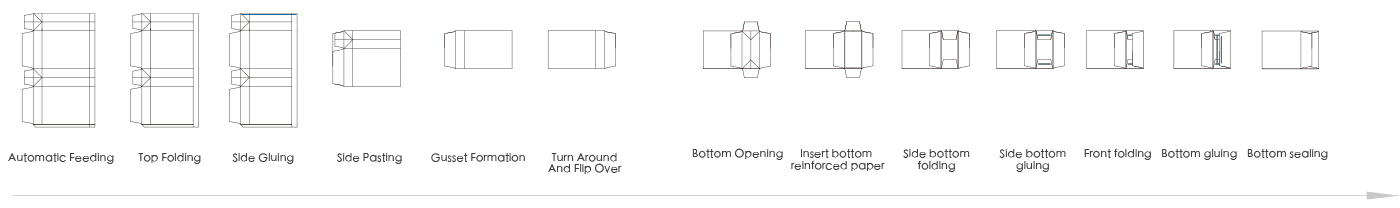

The basic working flow is sheet feeding, positioning, top folding (insert pasting), tube forming, gusset forming, bottom open, servo bottom cardboard inserting(split bottom), bottom gluing, compaction and output.

All these steps increase the bag making efficiency and save a lot of labor cost, replace the traditional manually paper bag making way. Realize automation, intelligent and high efficiency production requirement, which achieve the leading level in the world.

The feature of this model is Split Bottom, provides a one-stop solution for special paper bags.

Product Video

Technical parameter

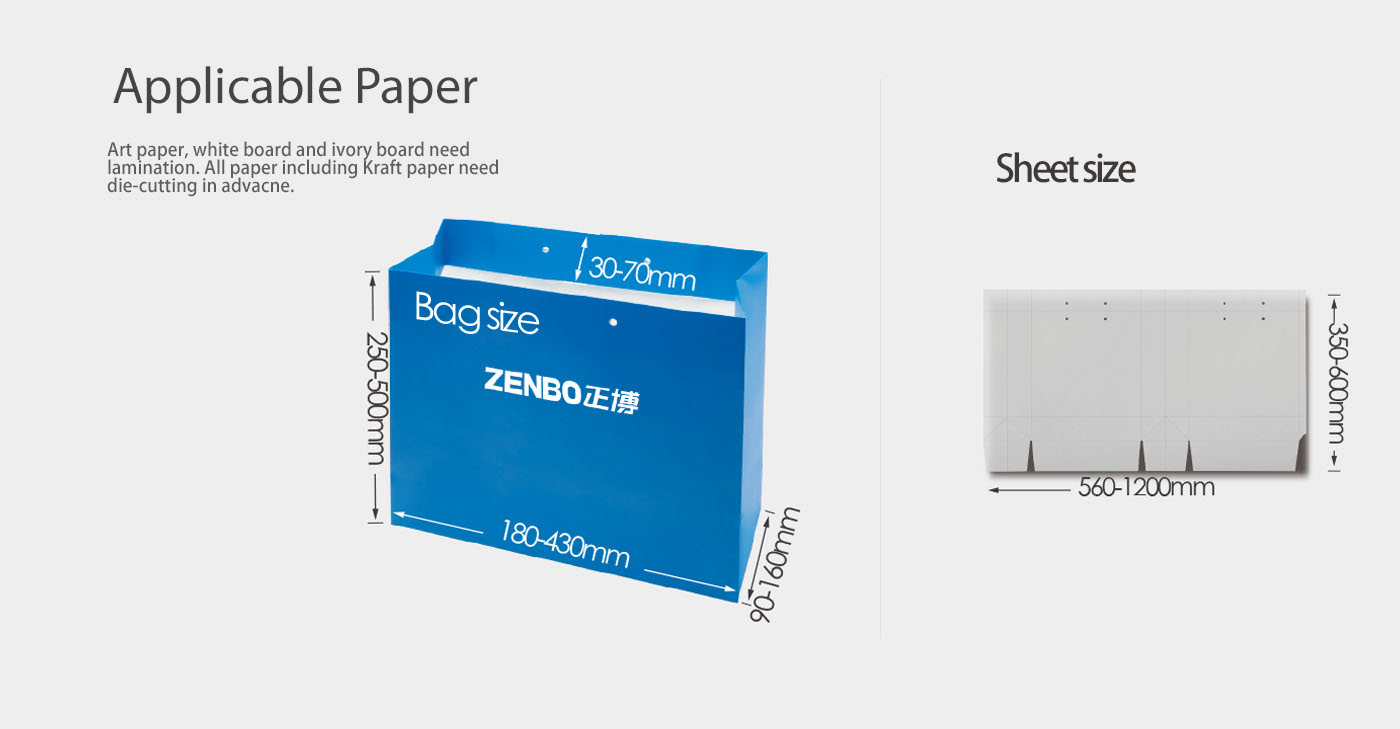

| Max.Sheet(LxW) | 1200x600mm |

| Min.Sheet(LxW) | 560x350mm |

| Sheet Weight | 200g-350g/m2 |

| Bag Height | 250-500mm |

| Bottom Width | 90-160mm |

| Bag Width | 180-430mm |

| Top Folding Depth | 30-70mm |

| Total Power | 13kw |

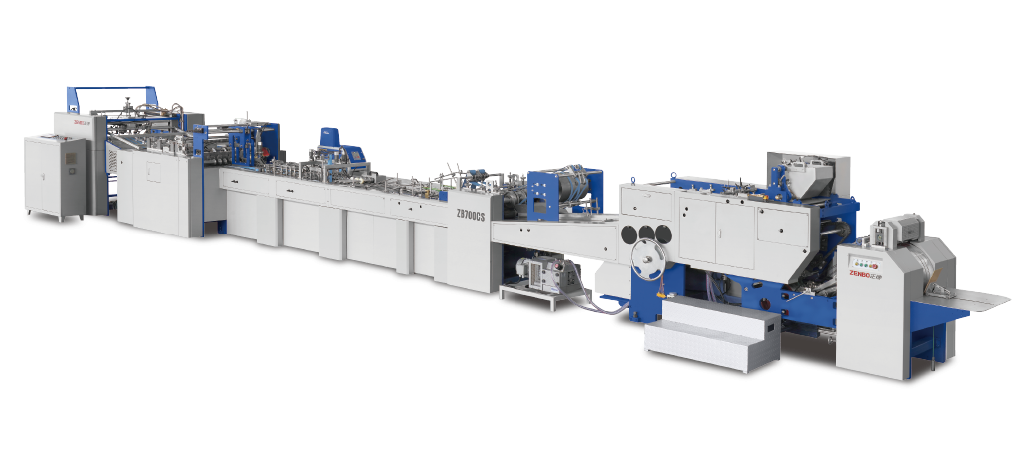

| Machine Size | 14860x4200x1800mm |

| 40-70bags/min | 50-80bags/min |

| Total Weight | 10T |

| Glue Type | Water soluble cold glue(hot-melt glue) |

Process flow